Where can I customize the best sweet packaging box?

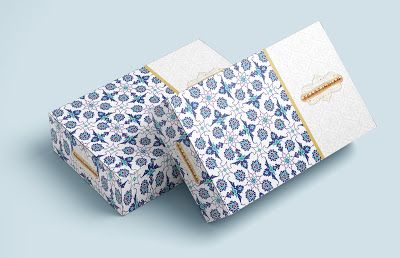

Packaging products as a modern commercial society, has the basic function of protecting, integrating, transporting and selling products, sweet packaging box design to complete the target function of packaging, sweet packaging box shape changes should take into account the protection, practicality and aesthetics, the design must be carried out under the guidance of certain design principles, requirements, norms and standards. The design must be guided by certain design principles, requirements, norms and standards. Adopting scientific and reasonable modelling and structural design methods can produce qualified and good packaging.

The concept and method of custom the best Sweet packaging box:

Due to the different types and functions of commodities, the requirements for packaging design are also different, such as sweet packaging box design should be safe and hygienic, and consider the problems of preservation and opening to meet the requirements of consumers. Therefore, the design of packaging box should be based on a series of conditions such as the nature of the product, its use, positioning, storage and transport conditions, and even mechanical principles, display and sales conditions, etc. According to the design requirements of the packaging box, a novel sweet packaging box should be created to meet the needs of the market.

At the same time, the design requires reasonable integration of various elements, box design procedures and standards, so as not to waste resources and increase the ineffective investment in enterprises, as the saying goes, "good steel on the knife edge" is true. If the effective cycle of edible products for one year, then the implementation of the packaging function of protection technology and packaging materials and process selection should also correspond to its life expectancy, to avoid over-packaging or weak packaging, in order to obtain the best comprehensive benefits, to win the market.

In addition, it should also meet the requirements of consumers' occupation, age, region, seasonality and the living habits of people of different nationalities and religious beliefs.

Comprehensive the above box design concepts and methods, and then add their own ideas, after many times of design and modification, through continuous improvement and innovation, and finally completed a sweet packaging box that they think is appropriate.

Customising the best Sweet packaging box material selection:

After years of development, especially in recent years, a series of reasons such as people gradually deepen their packaging and pursue product differentiation, the packaging materials have become extremely wide, even such as ceramics, leather, wood, silk, etc., can be used for packaging. Of course, the most commonly used types include paper, plastic, metal and glass.Fuliter Packaging as a professional paper packaging gift box manufacturer offers you a wide range of materials to customise your Sweet packaging box.

Kraft Paper.

Kraft paper is strong and is a very important packaging material commonly used for grocery bags and various shipping bags.

Bleached White Paper: Bleached white paper is another high quality packaging material.

Bleached white paper is another high quality material widely used for packaging and is often used to make paper bags or packaging pads to protect products.

Letterpress Paper: Letterpress paper is used for books and magazines.

Letterpress paper is the main paper used for booklet letterpress printing. It is suitable for important writings, scientific and technical books, academic publications, college and university technical teaching materials and other text paper.

Toppan paper has a uniform texture, no lint, slightly elastic, opaque, slightly water-resistant, have a certain mechanical strength and other characteristics.

Offset Paper.

Offset paper is mainly used in lithographic presses or other printing presses to print more advanced colour prints, such as colour magazines, brochures, posters, colour printed logos and some advanced books, as well as book covers, illustrations and so on.

Copperplate Paper.

Copperplate paper is also known as coated paper, this type of paper is made by applying a layer of white paste on the original paper and pressed. It is mainly used for printing albums, covers, postcards, exquisite product samples and colourful trademarks.

Art Paper.

Art paper, also known as fancy paper and speciality paper, is distinguished from ordinary printing paper, such as coated paper, offset paper and news wrapping paper.

These materials are widely used in the food packaging industry, in which some special printing process is added, as a gift packaging box can highlight the texture and taste. Of course, if you need customised Sweet packaging box, we will provide you with professional packaging advice to help you achieve better results with your Sweet packaging box.

Customised best Sweet packaging box printing process:

One of the most popular materials used for sweet packaging boxes is paper because of its eco-friendly and cost-effective nature. It offers a lightweight yet sturdy solution that is perfect for transporting delicate sweet packaging boxes. It also offers flexibility in terms of design and customisation, making it ideal for sweet packaging boxes.

The two most common techniques used for custom sweet packaging boxes are offset printing and digital printing.

Offset printing, also known as lithography, is a traditional printing method that provides excellent colour accuracy and high quality prints. In this process, the design is transferred from a metal plate to a rubber blanket and then to paper. This is a cost-effective option for large quantities of dessert box packaging as the set-up costs are relatively high, but the unit cost decreases as the quantity increases.

Digital printing is a more modern and flexible option for customised dessert box packaging. The technology allows for on-demand printing, which means there are no set-up costs and individual boxes can be printed as needed. Digital printing offers vibrant colours and crisp images, making it suitable for complex designs or small print runs. However, the cost per unit tends to be higher compared to high volume offset printing.

Once the printing process is complete, the dessert box receives finishing techniques to enhance its appearance and functionality. These techniques include lamination, topical varnishing, embossing and foil stamping. Lamination involves applying a thin plastic film to the printed surface to protect it from moisture and increase durability. Spot varnish is a glossy or matte coating applied to specific areas of a design to create contrast and highlight certain elements. Embossing usually adds texture to the packaging by raising specific parts of the design, while foil stamping uses metallic or holographic foils to add a luxurious touch.

The printing process plays a vital role in sweet packaging box customisation, allowing brands to create unique and attractive designs to attract customers. By utilising techniques such as offset and digital printing, brands can achieve high quality printing while taking into account budget and production requirements. In addition, finishing techniques such as lamination, topical varnishing, embossing and hot foil stamping add the finishing touches to sweeten the box, enhancing its visual appeal and functionality. With the right combination of design and printing techniques, dessert brands can stand out in the market and leave a lasting impression on customers.

Customising the best Sweet packaging box manufacturer of choice:

Finding a reliable and trustworthy manufacturer is crucial when it comes to sweet packaging boxes. Custom products, especially sweet packaging boxes, require attention to detail and quality materials.

Creative design capabilities:

The ability to provide unique and attractive design solutions based on the needs of the customer. It brings visual impact to the product and increases the added value of the product, as well as strikes a chord with consumers and enhances the willingness to buy.

High-quality material selection:

High-quality paper materials not only add texture to the appearance of the gift box, but also improve its durability and protection. Manufacturers should be able to choose different paper materials, including but not limited to high-gloss, matte, and textured paper, according to customers' requirements to meet their different needs for packaging gift boxes.

Accurate production capacity:

Being able to effectively plan and manage the production process to ensure the coordination and connection between various processes in order to improve production efficiency and production quality. In addition, the manufacturer should have advanced production equipment and technology to ensure product accuracy and consistency.

Customer service and communication skills:

Establish a harmonious communication relationship with customers in order to understand their needs and expectations and translate them into specific product design and manufacturing solutions. Responds to customer questions and requests in a timely manner, providing professional advice and support to ensure customer satisfaction with products.

Quality control and testing capability:

Establish a comprehensive quality management system to ensure that every step of the process, from raw material procurement to finished product delivery, meets the relevant quality standards and requirements. Product quality inspection and testing ensure the quality and reliability of the products.

Choosing a good customised sweet packaging box manufacturer requires a combination of factors. Fuliter would be a good choice in this regard.

The best customised sweet packaging boxes (why) can be found at Fuliter:

Superb technology and creative design:

Our team has a wealth of experience in box making and creative design capabilities. No matter what kind of customised boxes you need, we can provide you with a variety of creative design solutions according to your requirements and produce the finished products according to the highest quality standards. Our attention to detail and fine finishing ensures that each customised box displays a unique personality and quality.

Multiple material options & environmental sustainability:

We can choose from a wide range of materials to create boxes, such as cardboard and corrugated cardboard, according to the needs and requirements of our customers. We are very conscious of environmental sustainability, so we work with our suppliers to source only materials that meet environmental requirements. We provide renewable and recyclable packaging materials to reduce the impact on the environment.

Complete production facilities and quality management system:

Our factories are equipped with state-of-the-art production facilities and technology to ensure efficient production and quality finished products. We strictly adhere to the ISO quality management system and all boxes undergo stringent quality checks to ensure that the quality and appearance of each product is at its best.

Customised service:

We understand that every customer's needs and requirements for customised boxes are different, so we offer flexible customisation services. Whether you need unique sizes, special shapes, custom printing or special decorative effects, we can meet your requirements. Our team will communicate and work closely with you to ensure that the final box fully meets your expectations and needs.

Good after-sales service:

We always insist on customer satisfaction as the first principle. If you have any problems or dissatisfaction with our products or services, we will actively and promptly communicate with you to solve the problem and ensure your satisfaction at the highest level.

As a paper packaging box manufacturer, with our professional technology and ability, we can provide you with superb creative design, diversified material choices, perfect production equipment and quality management system, flexible customisation and excellent after-sales service. Whether we provide customised packaging boxes for individuals or enterprises, we have the ability to provide you with satisfactory products and services.

Post time: Dec-04-2023