china date packaging box suppliers

Nowadays, cartons are used in all walks of life, and different industries have different size requirements. No matter what manufacturer or industry, a large number of cartons are needed for turnover every year.

China date packaging box suppliers. To create originality and personality in packaging design, graphics are a very important means of expression. They play the role of a salesman, conveying the contents of the packaging to consumers through visual effects, and have a strong visual impact. It can attract the attention of consumers and generate the desire to buy.

China date packaging box suppliers, Packaging graphics can be summarized into three types: concrete graphics, semi-concrete graphics and abstract graphics. They are closely related to the packaging contents, so that the characteristics of the product can be fully conveyed. Otherwise, it will not have any meaning and cannot be associated with people. Seeing anything and not expecting it to have any effect will be the biggest failure of the packaging designer. Generally speaking, if the product is more physiological, such as eating and drinking, then more emphasis will be placed on the use of concrete graphics; if the product is more psychological, most abstract or semi-concrete graphics will be used.

China date packaging box suppliers, packaging graphics are related to the target audience, especially those under 30 years old. When designing product packaging graphics, you should take good care of it so that the designed packaging graphics can be recognized by the target of appeal and achieve the purpose of demand.

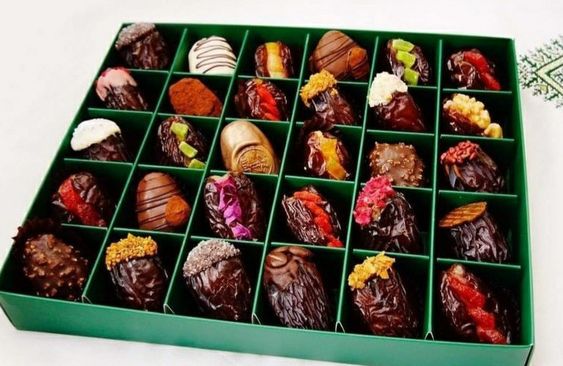

China date packaging box suppliers. Product reproduction can enable consumers to directly understand the contents of the package in order to produce visual impact and desired effects, usually using figurative graphics or realistic photographic graphics. For example, in food packaging, in order to reflect the deliciousness of the food, photos of the food are often printed on the product packaging to deepen consumers' vivid impression and create desire to purchase.

China date packaging box suppliers, "Touching scenes and emotions" means that things evoke similar life experiences and thoughts and feelings. It uses emotions as the medium to move from one thing to another, from the appearance of one thing to the appearance of another thing. Generally speaking, it is mainly based on the appearance characteristics of the product, the effect characteristics of the product after use, the rest and use state of the product, the composition of the product and the ingredients of the packaging, the origin of the product, the story and history of the product, the characteristics of the place of origin and national customs Design packaging graphics to describe the connotation of the product, so that people can think of the packaging content after seeing the graphics.

China date packaging box suppliers, Excellent packaging design makes people like it, praise it, and make people want to buy it. This factor that makes people like it is the symbolic effect emanating from the packaging. The function of symbols is to suggest. Although they do not directly or specifically convey ideas, the function of suggestion is powerful and sometimes exceeds concrete expression. For example, in the packaging design of coffee, a steaming packaging graphic symbolizes the fragrant quality of coffee. It also symbolizes that young men and women are indispensable drinks in love relationships and dates, to attract consumers.

China date packaging box suppliers, Different countries have different preferences and taboos on packaging graphics: Islamic countries prohibit the graphics of pigs, six-pointed stars, crosses, female human bodies, and thumbs up as packaging graphics, and like five-pointed stars and crescent graphics; Japanese people believe that lotus flowers It is unlucky, the fox is cunning and greedy, and the sixteen-petal chrysanthemum pattern used on the Japanese royal crest is not suitable for packaging. They like circles and cherry blossom patterns; the British compare goats to unruly men, and regard roosters as Obscene things, elephants are useless and annoying, and cannot be used as packaging graphics, but shield and oak graphics are preferred; Singapore is world-famous as the Lion City and likes lion graphics; dog graphics are from Thailand, Afghanistan, It is taboo in Islamic countries in North Africa; the French believe that walnuts are unlucky, and the spades pattern is a symbol of mourning; Nicaraguans and Koreans believe that triangles are unlucky, and these cannot be used as packaging graphics; some people in Hong Kong regard chicken as a synonym for prostitutes. Therefore, it is not suitable for bedding packaging graphics.

China date packaging box suppliers, Different from paper, corrugated cardboard is made by first processing the corrugated base paper into a corrugated shape, and then using adhesive to bond the surface and the middle corrugated layer from both sides, so that the middle layer of the cardboard has a hollow structure. It has high strength, stiffness, and durability. Compressive bursting strength, etc. Due to its special properties, it is now widely used in product packaging, and direct printing on corrugated paper has become the mainstream printing method for packaging boxes.

China date packaging box suppliers,In recent years, especially in Europe and the United States, ultra-thin and super-strong micro-corrugated cardboard has quietly occupied more and more corrugated cardboard markets, because it has the best physical properties and printing properties of corrugated cardboard and thick cardboard. Compared with traditional thick cardboard, it has the characteristics of good strength, strong buffering force, good elasticity, material saving, light weight, and good printing effect. Compared with traditional corrugated cardboard, micro-corrugated cardboard has the characteristics of small flutes, high stiffness, compact structure, strong and flat, light and thin material, good pressure resistance, and can be directly printed with an offset printing machine. In the past, it could only be printed on flexographic plates. The production process of direct printing on the printing machine and the production process of printing first and then laminating on the offset printing machine simplifies the process, shortens the production cycle, and improves production efficiency.

China date packaging box suppliers, Commonly used micro-corrugated boards include F-type (0.75mm), G-type (0.5mm), N-type (0.46mm), O-type (0.3mm), etc., all of which are composed of three layers, namely top paper, core paper and bottom paper. . At the same time, micro-corrugated cardboard also has the following characteristics:

(1) High strength, which can enhance the protective function of the product, and is 40% stronger than thick cardboard;

(2) Light weight, 40% lighter than thick cardboard, and 20% lighter than mounted corrugated cardboard %;

(3) Smooth surface, exquisite patterns, bright colors, and strong visual effects.

1. The principle of offset printing and its requirements for corrugated cardboard printing

China date packaging box suppliers,Currently, methods commonly used in corrugated cardboard printing include flexographic printing, gravure printing and offset printing of surface paper and then lamination. Among them, flexographic printing is the most commonly used, but the printing accuracy is not very high. Generally, it can only print some low-grade rough cartons, while gravure printing and offset printing are both pre-printing processes, that is, printing the tissue first and then printing Although bonding treatment can achieve better quality, the process is complicated and the cost is high. Therefore, offset printing directly on corrugated cardboard is a new process pursued by the packaging and printing industry. The current KBA Rapida 105 and Manroland 700 and 900 can directly offset print on micro-corrugated cardboard, and the printing quality can reach a very high level.

China date packaging box suppliers, Offset printing makes use of the natural law of immiscibility of oil and water. On a printing plate that is almost on the same plane, the picture and text parts only absorb ink, and the blank part only absorbs water. The picture and text ink is transferred to the substrate through a blanket. . Due to its high image restoration and color reproduction capabilities, offset printing is currently the most widely used and technically mature printing method. At present, it accounts for more than 50% of all printing in China, mainly paper printing. In recent years, with the rapid development of packaging printing, flexographic printing, gravure printing, and screen printing have made great progress, while the development momentum and proportion of offset printing have declined.

At present, due to the breakthrough in offset printing technology of printing directly on micro-corrugated paper, the offset printing process will be revived. In the field of traditional fiber cardboard boxes, such as wine, small appliances, footwear, hardware tools, microelectronics, computer software, counter sales displays, fast food, etc., offset printing has begun to compete with other industries due to its better printing quality. Traditional thick corrugated cardboard competes for the market.

However, fountain solution is used in offset printing (the fountain solution is mainly used to keep the blank part of the printing plate clean, and the main component of the fountain solution is water), which makes the offset printing process very complicated. The mixing of ink and water will produce ink emulsification, which will cause the paperboard to absorb water, deform, and change its strength, which will affect the color, viscosity, and drying performance of the ink. Therefore, the control of ink balance becomes very critical. If the amount of water is too large, the ink will be over-emulsified, drying will be slowed down, and the color will become lighter. In particular, the corrugated cardboard will absorb more water, which will reduce the compressive strength and surface strength, and may even cause it to collapse under the printing pressure.

As the size of the cardboard increases, the deformation of the surface paper and the inner paper are inconsistent, making the printing suitability worse. Therefore, the water volume control for direct offset printing of corrugated cardboard is stricter than that of ordinary paper printing. And if the amount of ink is too large, problems such as dot expansion, layer merging, and smearing will occur. Therefore, the ink and ink balance must be controlled during the printing process, especially the amount of water.

Direct offset printing on corrugated cardboard requires lighter weight than ordinary paper in terms of pressure control. Since the middle corrugated corrugated cardboard is hollow, if the pressure is too high, faults such as dot expansion and layer merging will occur. At the same time, a "washboard" phenomenon will occur, and in severe cases, crushing will occur. Therefore, the pressure control needs to be more precise.

Due to the special structure and special requirements of corrugated cardboard, this type of offset printing machine generally uses a special rubber blanket with good compressibility and a certain hardness, so that the different compression resistance of the corrugated cardboard surface can be compensated for through the compression deformation of the blanket. performance and deformation performance to improve printing quality.

2. The impact of offset printing on corrugated cardboard printing

(1) Effect on the strength of corrugated board

The huge pressure of offset printing will reduce the compressive strength of corrugated cardboard; the use of fountain solution will reduce the surface strength and compressive strength of cardboard due to water absorption.

(2) “Washboard” phenomenon

The washboard phenomenon is the most common quality problem in corrugated cardboard printing. This phenomenon may occur if the pressure and ink volume cannot be well controlled during printing.

(3) Imbalance of ink and ink

In offset printing, the biggest impact on quality is the balance of ink and ink. In particular, excessive water has a greater impact on micro-corrugated board.

(4) Acidity and alkalinity of fountain solution

If the acidity is too strong, it will slow down drying and corrode the printing plate; if the acidity is too weak, it will not be able to form an effective hydrophilic protective layer on the blank part of the printing plate.

(5) Performance of rubber cloth

The properties of the blanket include surface properties and compression deformation properties. Surface properties are the guarantee for absorbing ink and transferring ink, while compression deformation properties are the basis for obtaining high-quality images on corrugated board.

Direct offset printing micro-corrugated cardboard is a brand-new printing process that has reached a very high level in terms of printing effect and printing quality. It is basically comparable to the printing quality of paper. It will become a high-end corrugated box and carton. Paperboard, the first choice for packaging, can bring huge economic benefits to packaging and printing companies, and is one of the main directions for the development of offset printing in the future. This has reignited a bright light for the development of offset printing.

Post time: Nov-14-2023