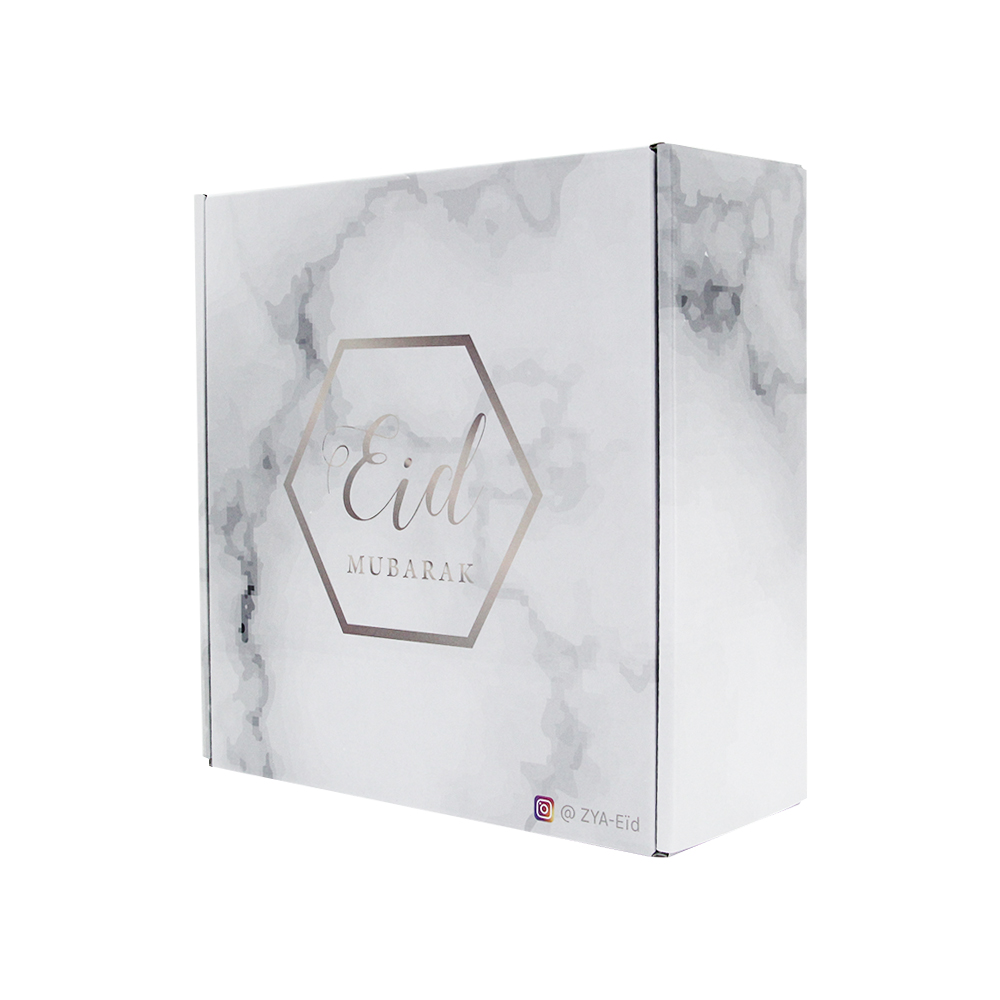

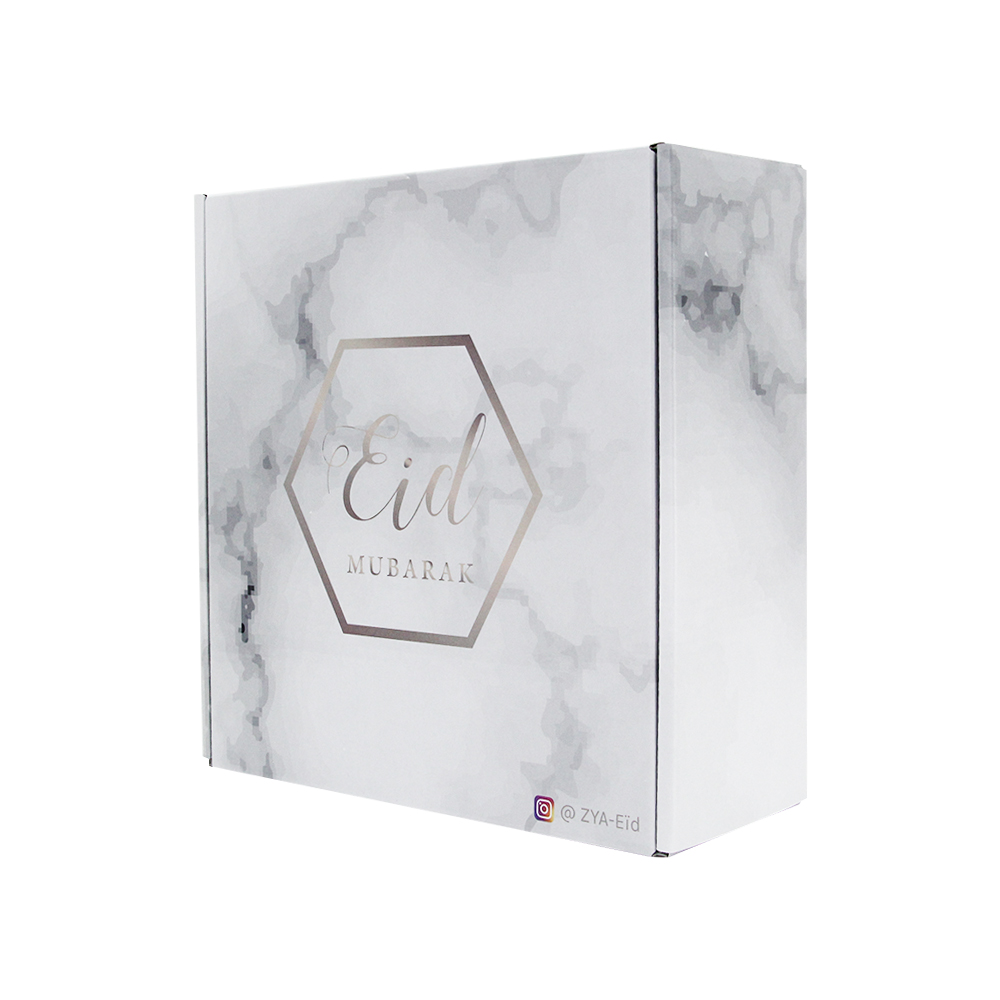

carton custom cardboard corrugated wholesale packaging shipping mailer paper box with logo for custom mailing box

carton custom cardboard corrugated wholesale packaging shipping mailer paper box with logo for custom mailing box

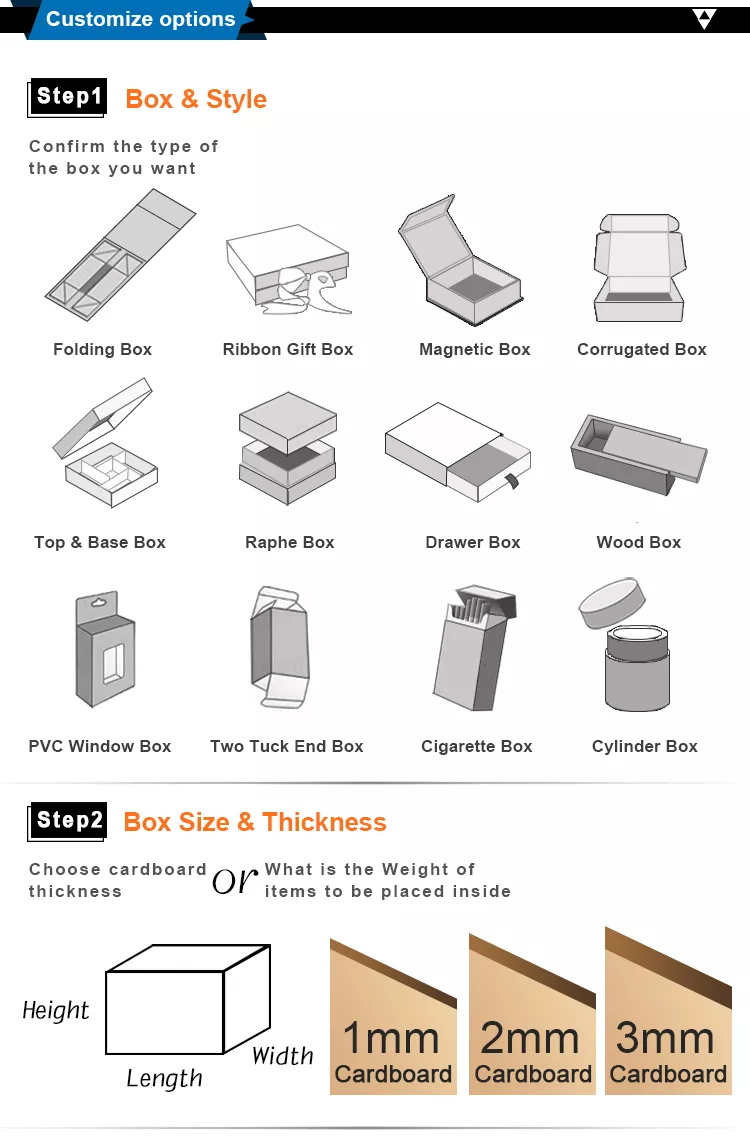

Specification

|

Dimensions |

All Custom Sizes & Shapes |

|

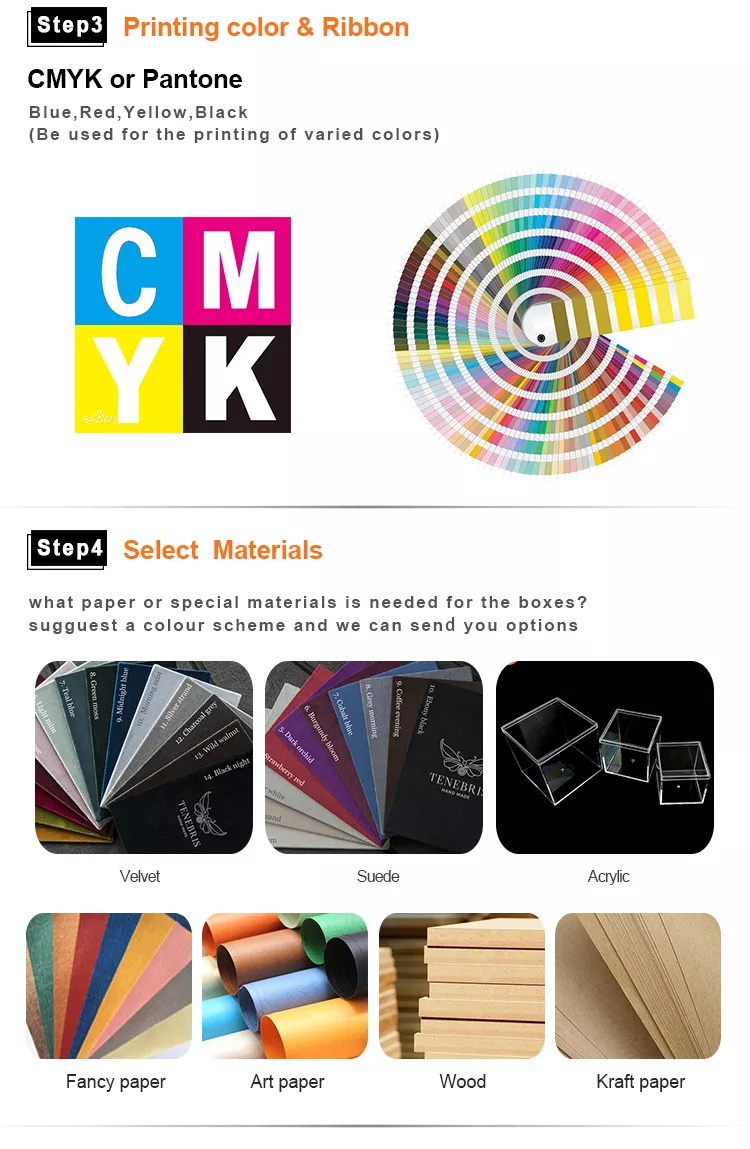

Printing |

CMYK, PMS, No Printing |

|

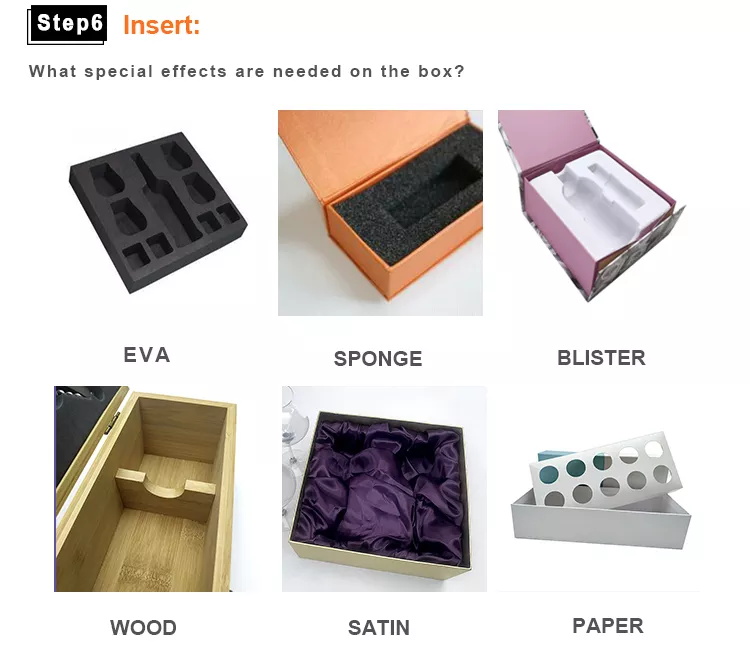

Paper Stock |

Art paper |

|

Quantities |

1000 - 500,000 |

|

Coating |

Gloss, Matte, Spot UV,gold foil |

|

Default Process |

Die Cutting, Gluing, Scoring, Perforation |

|

Options |

Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

|

Proof |

Flat View, 3D Mock-up, Physical Sampling (On request) |

|

Turn Around Time |

7-10 Business Days , Rush |

Packaging boxes for confectionery and candy

Packaging boxes are an important part of selling confectionery and candy, cake box and need to strike a good balance between protective properties, cake box cookies attractiveness, portability and brand value.

Choose materials that meet food packaging standards, such as cardboard, folding boxes, and plastic boxes that are not easily deformed are common choices.how to make box cake better

Easy to carry and store, so the box size, shape and weight need to consider the needs of consumers.

For confectionery and candy, cake boxes the use of brand colors and logos, as well as highlighting brand values and selling points, can help increase brand awareness and value.box cake

Packaging box design and printing process analysis

Packaging boxes are an essential part of any product. It's the first thing consumers see and it conveys a lot about the product. In today's market, packaging boxes are used as a marketing tool to stand out from competitors. Therefore, having a well-designed packaging box is crucial, and the printing process plays a pivotal role in it.box cake hacks

Designing a packaging box is not just about creating something attractive. It needs to be functional, economical and environmentally sustainable. The design process includes determining the purpose of the box, target audience, branding and material selection. Boxes must protect the product during shipping, storage and handling. It must also be visually appealing, easy to open and store. The box design must be consistent with the brand identity and create brand awareness.how to make a box cake better

Once the box design is finalized, the printing process comes into play. The printing process is critical to creating a visually appealing box and communicating your brand message. There are a variety of printing methods available, including digital printing, offset printing, flexographic printing, and gravure printing. make box cake better The printing method chosen depends on budget, product type and number of boxes required.

Digital printing is suitable for small batches and offers quick turnaround times. It is cost-effective and suitable for boxes with a variety of designs. The disadvantage of digital printing is that the color gamut is limited, and some complex colors may not be printed accurately.the cake box

Offset printing is the most commonly used printing method for packaging boxes. It is best suited for high volumes, high image quality and accurate color reproduction. Offset printing has a wider color gamut and can produce accurate colors that are consistent across print runs. It is also known for its cost-effectiveness, making it a popular choice in the packaging industry.box cake recipes

Flexographic printing involves a flexible letterpress mounted on a rotating cylinder. The printing plate is inked and transfers the image onto the box material. wholesale cake boxes Flexo printing is suitable for printing on a variety of materials, including plastics, paper and foil. It is cost-effective, fast and efficient, with good image quality and color reproduction.cake box cookie recipe

Gravure printing involves engraving an image onto a cylinder, which is then inked and transferred to the box material. Gravure printing is ideal for printing high-resolution images, producing excellent color fidelity. But it is expensive, time-consuming and not suitable for small batch production.how to make box cake moist

In conclusion, designing and printing packaging boxes requires careful consideration of various factors. Boxes had to be functional, environmentally sustainable, visually appealing and consistent with the brand identity. The printing process plays an important role in achieving these goals, and the printing method chosen depends on the budget, type of product and desired run run. A well-designed and printed packaging box can add significant value to a product and create a memorable experience for consumers.x box cake

420 Lucky

Cartel Flowers

Coral Path

Guess Jeans

Homero Ortega

J.P.Morgan

J’Adore Fleures

Maison Motel

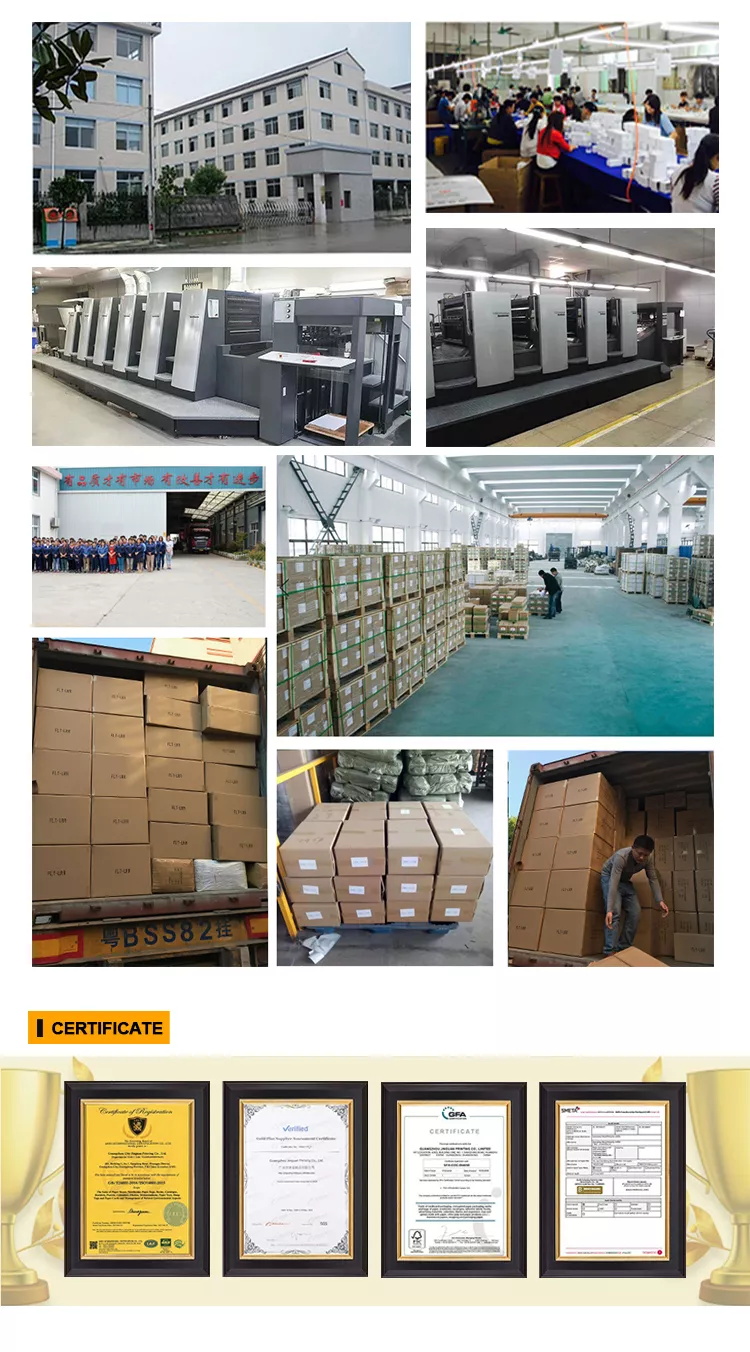

About us

Dongguan Fuliter Paper Products Limited was established in 1999,with more than 300 employees,

20 designers.focusing & specializing in wide range of stationery & printing products such as packing box、gift box、cigarette box 、acrylic candy box 、flower box、 eyelash eyeshadow hair box 、wine box 、 match box 、toothpick、hat box etc.

we can afford high quality and efficient productions. We have a lot of advanced equipment, such as Heidelberg two, four-color machines, UV printing machines, automatic die-cutting machines, omnipotence folding paper machines and automatic glue-binding machines.

Our company has integrity and quality management system, environmental system.

Looking ahead,we firmly believed in our policy of Keep doing better,make the customer happy. We will do our utmost to make you feel like this is your home away from home.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed

-

Phone

-

E-mail

-

Whatsapp