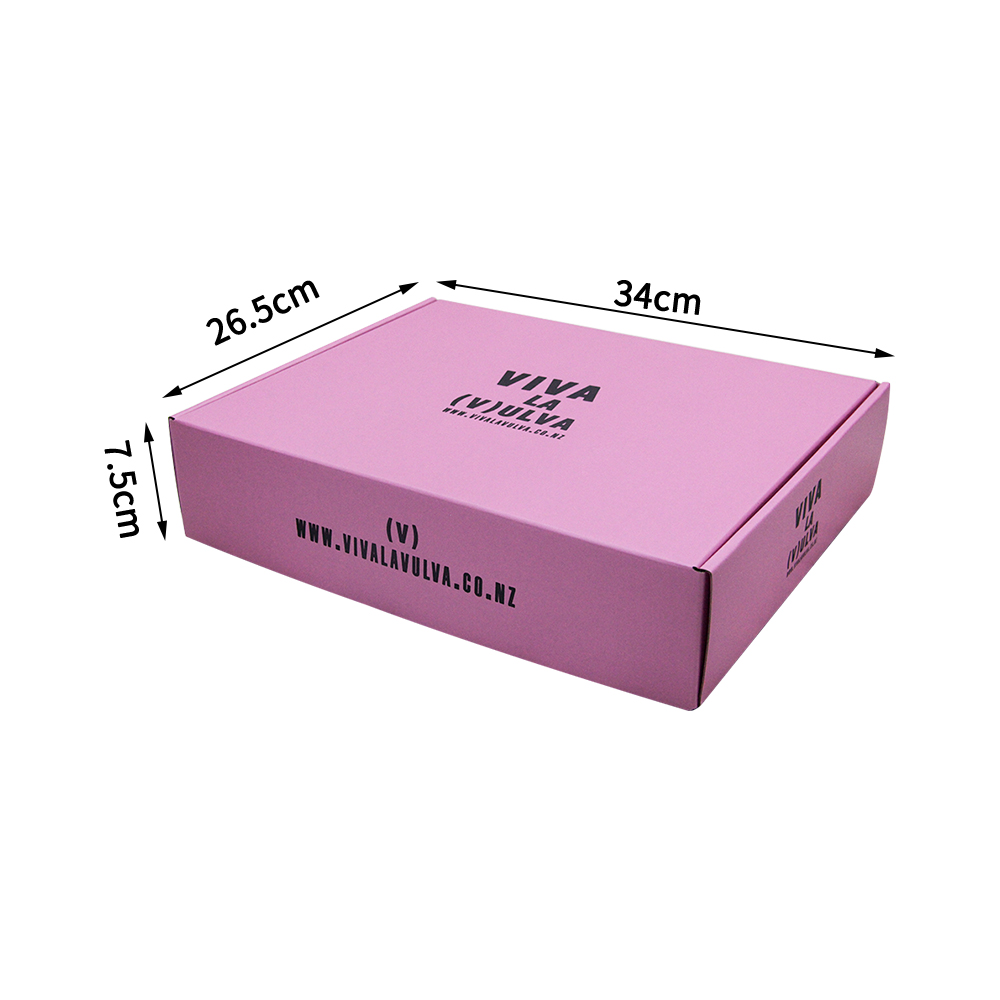

Custom Logo Pink Shopping Maile Box Wholesale

Custom Logo Pink Shopping Maile Box Wholesale

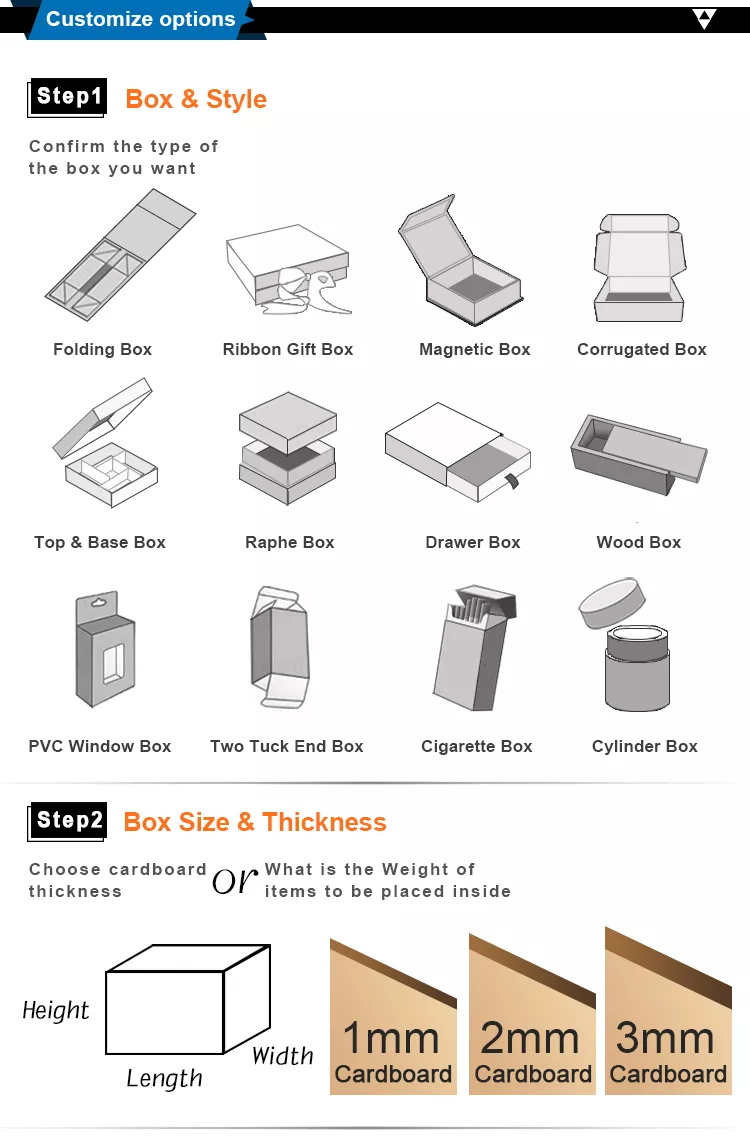

Specification

|

Dimensions |

All Custom Sizes & Shapes |

|

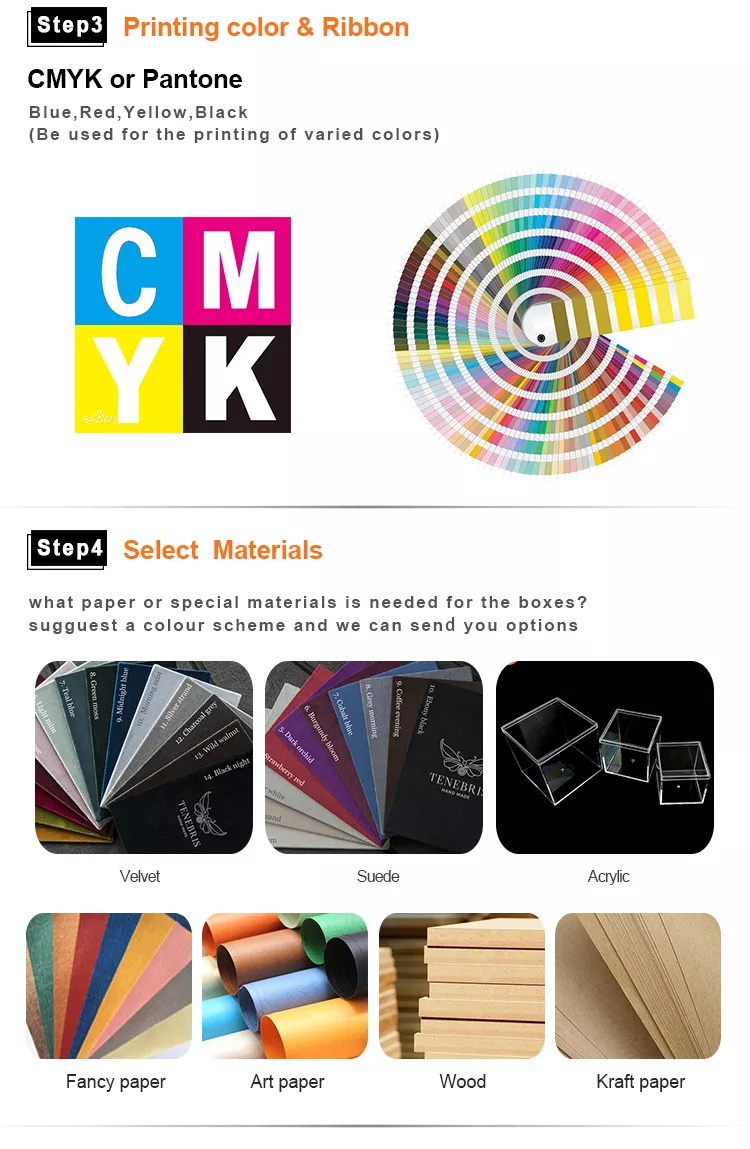

Printing |

CMYK, PMS, No Printing |

|

Paper Stock |

Copperplate paper + double gray |

|

Quantities |

1000 - 500,000 |

|

Coating |

Gloss, Matte, Spot UV,gold foil |

|

Default Process |

Die Cutting, Gluing, Scoring, Perforation |

|

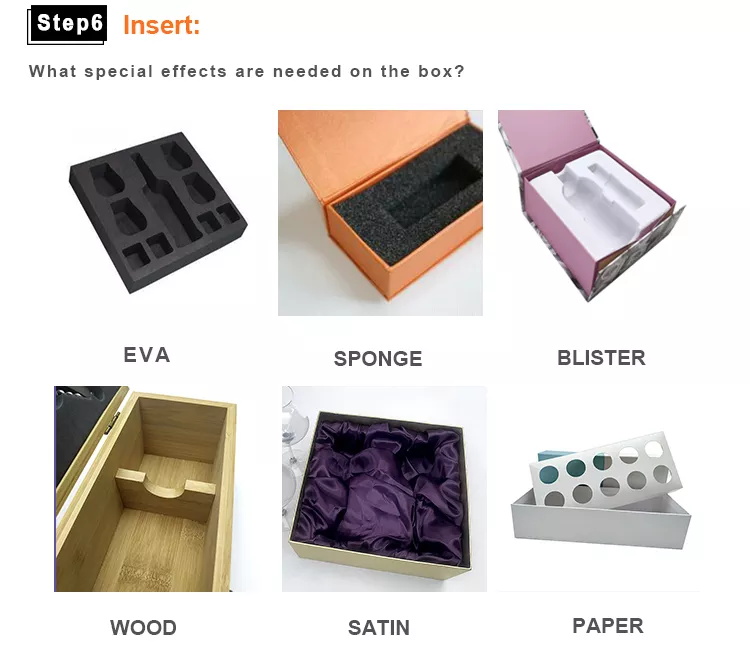

Options |

Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

|

Proof |

Flat View, 3D Mock-up, Physical Sampling (On request) |

|

Turn Around Time |

7-10 Business Days , Rush |

Does the appearance of the box matter?

In our daily life, goods are often found in some products that can make us shine, when people's attention to the product and brand will be greatly enhanced, the result is a beautiful packaging design, beautiful and unique packaging design has the effect of "silent salesman", so the packaging design should be considered from an aesthetic point of view.

The girly pink used in this box is so inclusive that even slightly larger items can fit in, making it eye-catching, especially to gain the love of many women, resulting in a pleasant shopping experience.

The production process of the packaging box

The production process of paper-wrapped gift boxes is a complex process involving several stages. It is important to note that the process varies depending on the type of paper-wrapped gift box being produced.

The first step in the production process of paper packaging gift boxes is to choose the appropriate paper type. The type of paper chosen depends on the characteristics of the gift box being produced. For example, if producing rigid boxes, thicker, stiffer paper is required.

The second step in the production process is design. This step involves creating a mockup of the gift box and determining the size, shape, and other specifications. This is an important step as it ensures that the size and shape of the gift box meets the customer's requirements.

The third step in the production process is to prepare the paper. This involves cutting the paper to the desired size and shape. The paper is then folded and scored to create the desired box structure.

The fourth step in the production process is printing the design and branding on paper. This is an important step because it adds the finishing touches the gift box needs. Depending on the type of gift box produced, it can be printed using various techniques such as lithography, embossing and hot stamping.

The fifth step in the production process is the coating of the paper. This is done to enhance the durability and appearance of the gift box. The coating process is to apply a layer of special paper coating material on the surface of the paper. This can be done using techniques such as UV coating, water-based coating or varnish application.

The sixth step in the production process is the die-cutting of the paper. This step involves cutting the paper into the desired size, shape and structure. This is an important step as it ensures that the shape and size of the gift box is exactly as required.

The seventh step in the production process is the folding and gluing of the paper. This step involves folding the paper into the desired structure, then gluing the edges together to create the gift box. The glue used is usually water-based, non-toxic and environmentally friendly.

The eighth and final step in the production process is finishing. This involves applying any finishing touches to the gift box such as ribbons, bows and other decorations. The gift box is then carefully inspected to ensure it meets the required standard.

To sum up, the production process of paper packaging gift boxes is a complex and meticulous process involving multiple stages. It is important to note that each stage is equally important and must be executed with precision and care. The final product is a beautiful and durable gift box that meets the client's requirements.

420 Lucky

Cartel Flowers

Coral Path

Guess Jeans

Homero Ortega

J.P.Morgan

J’Adore Fleures

Maison Motel

About us

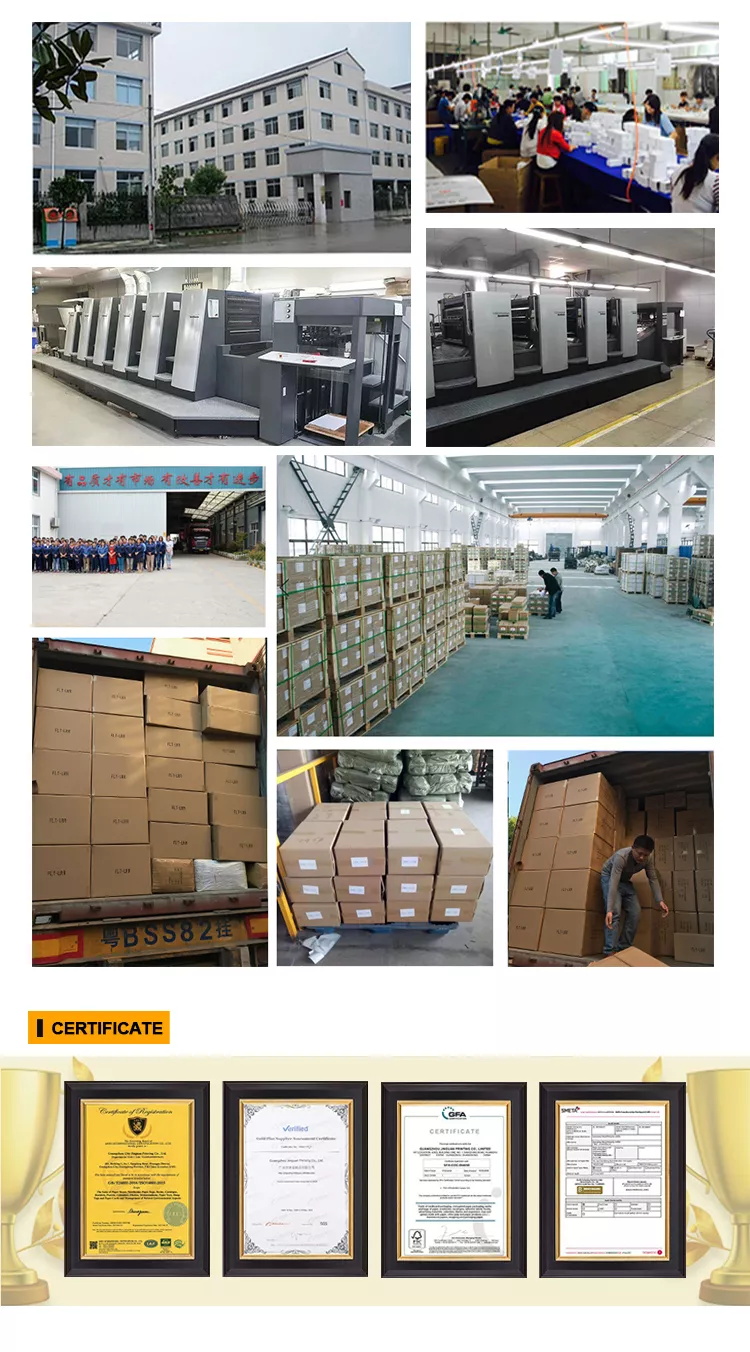

Dongguan Fuliter Paper Products Limited was established in 1999,with more than 300 employees,

20 designers.focusing & specializing in wide range of stationery & printing products such as packing box、gift box、cigarette box 、acrylic candy box 、flower box、 eyelash eyeshadow hair box 、wine box 、 match box 、toothpick、hat box etc.

we can afford high quality and efficient productions. We have a lot of advanced equipment, such as Heidelberg two, four-color machines, UV printing machines, automatic die-cutting machines, omnipotence folding paper machines and automatic glue-binding machines.

Our company has integrity and quality management system, environmental system.

Looking ahead,we firmly believed in our policy of Keep doing better,make the customer happy. We will do our utmost to make you feel like this is your home away from home.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed

-

Phone

-

E-mail

-

Whatsapp